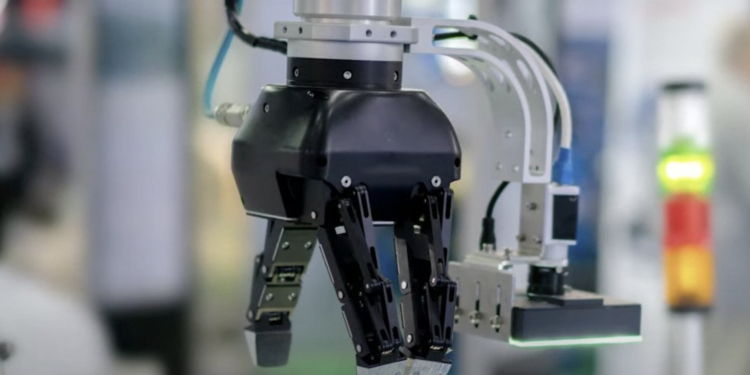

Industrial automation is a rapidly growing field, with numerous advancements made in recent years to make the process of automating various tasks faster, more efficient, and cost-effective. One of the key components of any industrial automation system is the gripper – the device that holds carries, and releases objects. When it comes to choosing the right gripper for your industrial automation system, you have two main options: pneumatic grippers and hydraulic grippers. But which one is right for your specific needs? In this article, we’ll take a closer look at the key differences between pneumatic and hydraulic grippers and help you determine which type of gripper is best for your application.

What are Pneumatic Grippers?

Pneumatic grippers are powered by compressed air and are used in applications where speed and precision are critical. The grip force of a pneumatic gripper can be adjusted by changing the air pressure, allowing for greater flexibility. Pneumatic grippers are a popular choice for many industrial automation applications, due to their relatively low cost, ease of maintenance, and the fact that they can be easily integrated into most pneumatic systems.

What are Hydraulic Grippers?

Hydraulic grippers, on the other hand, are powered by hydraulic fluid and are typically used in applications where high force and long cycle times are required. They are typically made up of a series of hydraulic cylinders that act as fingers, and they can be controlled by a central hydraulic valve. Hydraulic grippers are more expensive than pneumatic grippers, but they offer superior grip strength and are ideal for heavy-duty industrial automation applications.

Key Differences Between Pneumatic and Hydraulic Grippers

When it comes to choosing between pneumatic and hydraulic grippers, there are several key differences to consider. Firstly, pneumatic grippers are typically faster and more precise than hydraulic grippers, making them ideal for applications where speed and accuracy are critical. Secondly, pneumatic grippers are usually less expensive than hydraulic grippers, making them a more cost-effective option for many industrial automation applications.

On the other hand, hydraulic grippers offer superior grip strength, making them ideal for heavy-duty industrial automation applications. They are also more reliable in high-temperature environments, and they are typically more durable than pneumatic grippers. Additionally, hydraulic grippers are ideal for applications that require long cycle times, as they can hold and release objects with consistent force over extended periods of time.

Choosing the Right Gripper for Your Industrial Automation Needs

When it comes to choosing the right gripper for your industrial automation system, the key is to consider your specific application requirements. If speed and precision are critical, a pneumatic gripper is probably your best option. If, however, you need a gripper that can handle heavy loads and operate for long periods of time, a hydraulic gripper may be a better choice.

In conclusion, pneumatic and hydraulic grippers both have their own unique advantages and disadvantages, and the type of gripper you choose will depend on your specific industrial automation needs. So, whether you’re looking to automate a single task or an entire production line, be sure to choose the gripper that best fits your application requirements.